Concrete Jacking: Foam As The Ultimate Solution

I’ve used mudjacking for concrete leveling the past, and it’s worked well. Why would I choose a poly foam process now? Read on to make an informed decision!

Process Comparison

Conventional concrete leveling uses a simple process that is similar whether you are using foam or mud: drill, pump, patch. See the table below for a comparison between the two processes.

| Process Step | Poly Foam Concrete Leveling | Mudjacking |

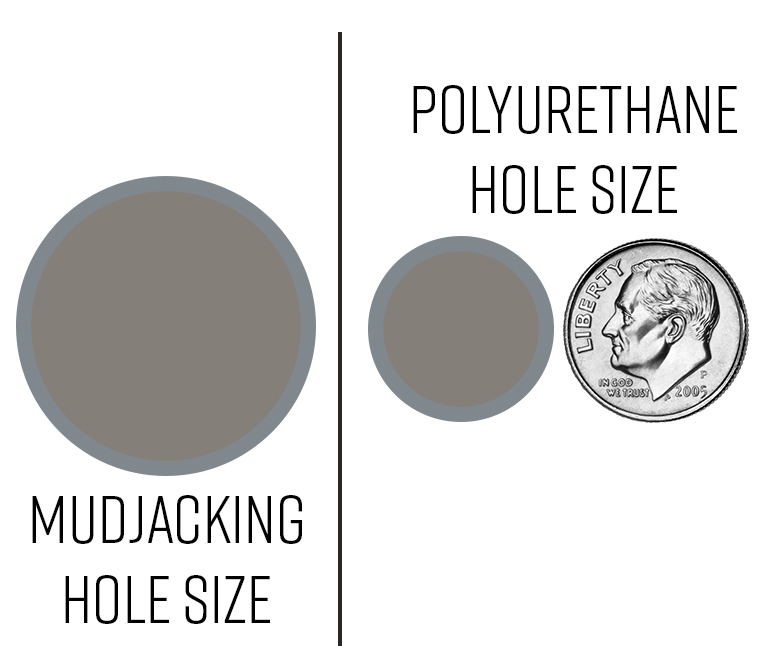

| 1. Drill | Drill holes 3/8” to 5/8” in diameter | Drill holes 1.5”-2” in diameter |

| 2. Pump | Insert ports and inject a two-part foam in a liquid state which subsequently creates a foam pillow to level the concrete. | Insert hose and use pressure from the mud pump to create lift directly beneath and adjacent to the drilled port. |

| 3. Patch | Patch holes. You are left with a rock-size patch. | Patch holes. You are left with a larger patch that is more noticeable |

Technical Discussion on the tradeoffs:

Hole size

Aesthetically, the hole size for poly foam leveling is much smaller than that of mudjacking. In stamped concrete or tile floor applications, a 3/8” port can be used and is drilled in the grout lines to better hide the patches.

Weight of Material Used for Concrete Leveling

Unsurprisingly, poly foam is much lighter than mud used in the mudjacking process. In situations where the soil bearing capacity is already marginal, poly foam minimizes additional weight and can also be used to perform a process called deep foamjection to increase soil bearing capacity using the same holes.

Which solution does a better job filling the void created by lifting?

As the lift progresses, a void is created beneath the slab. See the visual below to for an illustration on how mud fills the void vs foam.

As you can see, mud fills the void in a conical shape and doesn’t spread as far (depending on the consistency of the slurry mixture mixed by the operator). Because the foam travels in its liquid form and then makes foam, a much more complete lift and support matrix is created.

Longevity of the Concrete Leveling Technology

Poly foam’s biggest enemy is the sun. It does not do well against UV light. However, there is a severe absence of sun beneath your concrete, making it an extremely reliable solution for lifting concrete! It does very well in the presence of all environmental conditions beneath a slab, including water, which erodes mud! Now consider the presence of water and how it erodes dirt. The lack of resistance to water is one of the downfalls of mudjacking. Not only will the adjacent soils erode, but the mud itself will also erode in the presence of water.

Remember that no soils stand the test of time in the presence of water. Water puts soil particles in suspension and carries them away ever so slowly. For this reason, proper maintenance of your concrete is very important. Keep all open cracks/joints properly sealed, and keep all slabs properly backfilled. Anytime you can see the bottom of a slab, future problems are inevitable.

Concrete Leveling Process Cost Comparison

Poly foam is widely understood to be more expensive than mud-jacking. As discussed in this article, there are technical tradeoffs that influence someone to use one process over the other.

Install Time

Most projects can be done inside of a day or two, whether you are using mud or poly foam.